Ecossistema Wialon

Soluções

Produtos de nicho para tarefas específicas

Rastreamento de veiculos de leasing

Rastreamento da localização de veículos para empresas de empréstimo, leasing e financiamento automotivo

Controle de operações agrícolas

Controle a rotação de culturas e trabalhos de campo com Hecterra

Monitoramento de entregas

Desenvolvemos o Logistics para você gerir operações de delivery

Monitoramento de comportamento de motoristas

Eco Driving – a solução para monitorar a qualidade da condução

Gestão de manutenção

Um aplicativo web para planejar, controlar e registrar gastos com manutenção

Rastreamento de trabalhadores de campo

O WiaTag transforma um smartphone em um rastreador GPS e permite controlar operações de campo e a performance de equipes móveis

Gestão de transporte público

O NimBus foi projetado para controlar veículos de rotas fixas

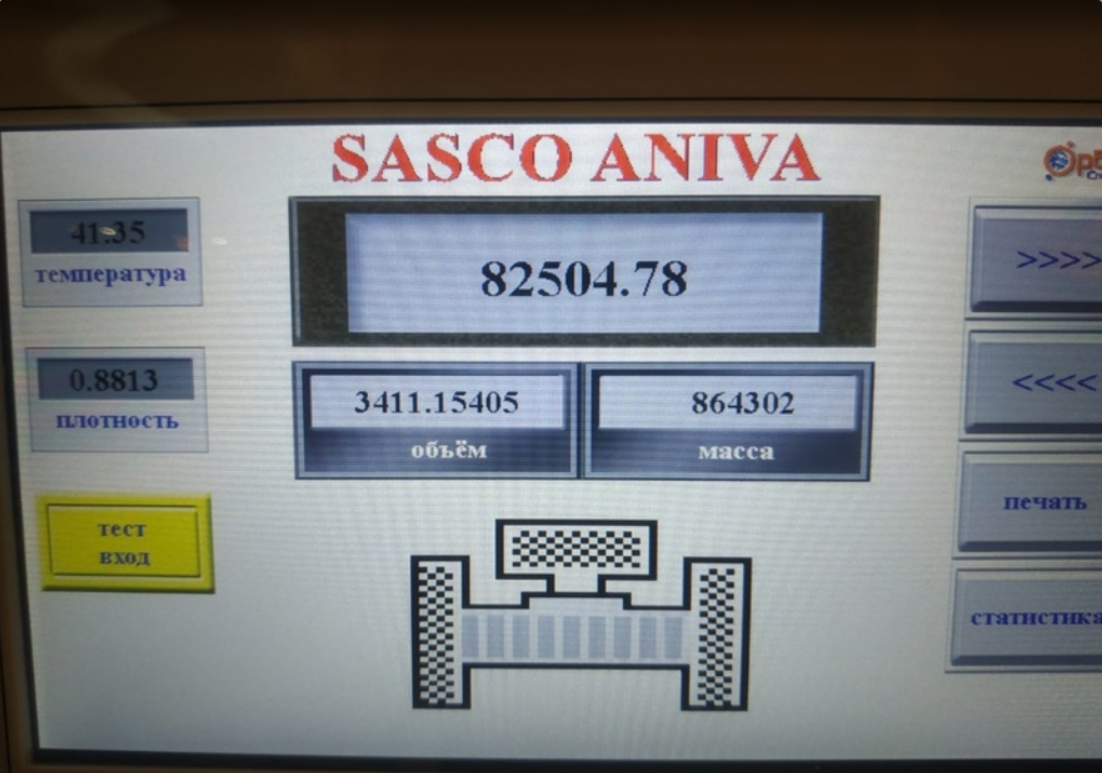

Controle de combustível

O módulo é projetado para calcular o consumo de combustível em qualquer tipo de maquinário, de veículos comuns à caminhões tanque

Hardware

Recursos

Comunidade

Contato

Conta pessoal